Ready to buy a rolling mill? Let's take a look....

Woop woop – So you’re thinking of investing in a rolling mill!!! My god, they really are beautiful pieces of equipment. My main mill even has a name since I love him so much (I honestly don’t know why I decided it’s a he, but he is a beast).

In my opinion, this is one piece of equipment you don’t want to scrimp on if at all possible. I love my cheap saw, and I have more fabulous pairs of cheap pliers than I have pairs of shoes, but I PERSONALLY would prefer not to buy a budget rolling mill. For the simple reason: you will want to upgrade eventually!!

But which is the best rolling mill?

On the market today, you can’t go wrong with a Pepe or Durston brand rolling mill. As a Sheffield lass, steel is in my blood, and there are no finer companies for rolling mills than these guys!

But before diving in and ordering the first Durston or Pepe mill you lay your eyes on, there are a few things to consider first:

What do you want to do with it? I can hear you now – well I want to roll bloody metal….. ha ha OK, I’ll be more specific. Do you want to be able to just roll flat sheet? Or do you want to be able to roll square and half round wire too? Or even get fancy and roll round wire, triangle wire and comfort fit wire – Yesssss, it’s all possible!!!!

If you want to just roll sheet, then a flat rolling mill is the perfect option. This simply consists of two round rollers that are perfect for rolling sheet metal as well as using for roller printing.

If you want to roll just wire, then you can get an all-wire rolling mill. The rollers on these are made for specific profile wires and you can generally choose from square and half round, which I have found is more than enough. But in some cases you can even get triangular, fully round, and comfort fit rollers too!

Or if you’re like most of us and you want a mill that will roll sheet and wire, then that is a combination rolling mill.

How much effort do you want to put into rolling? Rolling mills generally come with gears to reduce the amount of effort needed to roll the metal. The more gears, the easier and smoother the roll. Basically if a rolling mill has a gear ratio of 4:1, you’ll need to turn the handle 4 times for the rollers to rotate once. Personally I wouldn’t want to use a rolling mill with less than a 4:1 gear reduction as it’s bloody hard work and the results are not as even. A rolling mill with no gear reduction is known as a direct drive – personally, I don’t like them.

How wide sheet you want to be able to roll? I generally don’t roll metal that’s much wider than 3 inches (76mm), but that didn’t stop me getting the full 6 inches of flat space for rolling sheet. I probably wasted a little money there always thinking bigger is better! But always check under the specs to see how wide that flat rolling space is, especially when buying a combination mill (one that rolls wire and sheet).

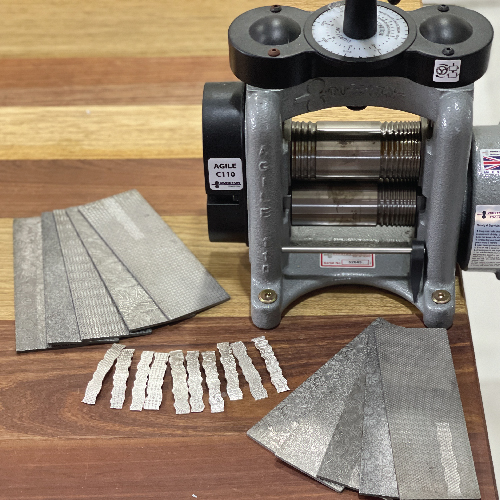

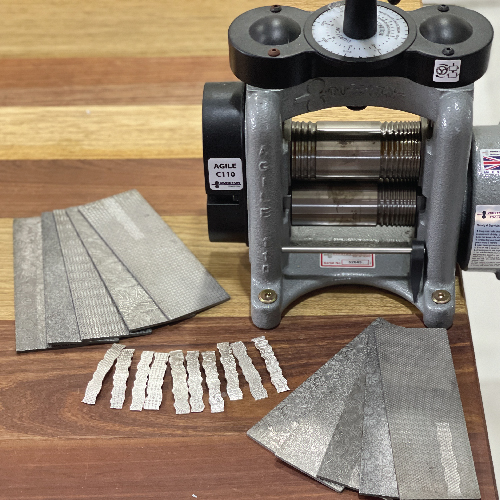

What thickness (gauge) of metal you want to be able to roll? My rollers open up to 6mm for my Durston Double D4 model and 5.5mm on my Durston Agile C110. Both of which are more than enough for roller printing with texture plates and rolling down any sheet that I need from melted scrap. If you are intending on doing a lot of roller printing, just take a measurement of the sheet, plate and sandwich material (I usually use paper and foam), and make sure the rollers open wide enough to accommodate this.

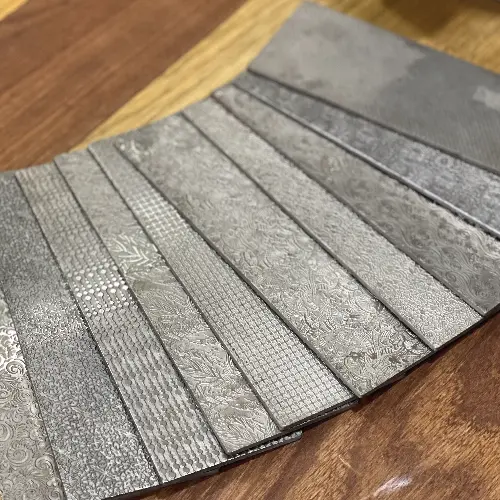

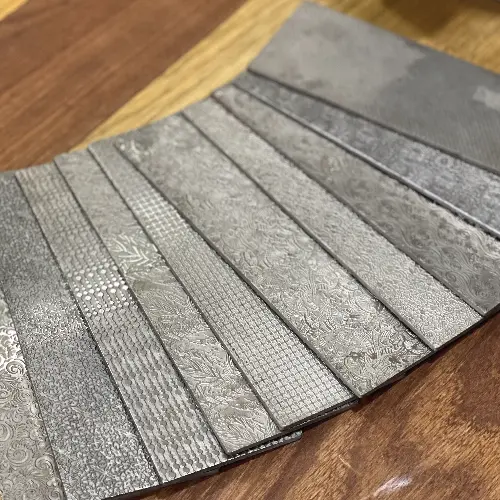

If you want a rolling mill that rolls both wire and sheet, you’ll want to look at getting a combination rolling mill. There are many options available offering various combinations of wire rolling and sheet rolling space to suit specific requirements. Again though, before buying take some time to think about what you need – more space for rolling sheet or more options for wire. If you’re going to be using texture plates such as those pictured, you’ll need to consider the width of these too – as ideally you’ll need a flat roller area large enough to accommodate these.

We proudly partner with Pepe Tools and Durston Tools

I’ll be honest with you, I wouldn’t partner with a shite company – and I’ve been asked, I promise!! So if I were just starting out, considering I need 2.5 inches (63.5mm) to roll my favourite texture plates from Oregon Trail Silver, as well as rolling smaller flat sheets, and I need to roll square wire too, here is what I would personally consider:

160MM Combination Ultra Mill with Ductile Frame from Pepe Tools.

Here are the important specs:

• Flat rolling area: 77mm

• Max square wire size: 6mm (9 square groves)

• Half round wire capabilities (width): 2.5mm, 3mm, 3.5mm, 4mm, 4.5mm, 5mm and 6mm

• Gear reduction: 4:1

• Maximum distance between rollers: 7mm

• Roller diameter: 60mm

• Weight: 30KG

DRM C130RE Combination mill from Durston tools

Here are the specs:

• Flat rolling area: 80mm

• Max square wire size: 8mm (11 – square wire grooves)

• Half round wire capabilities (width): 1.5mm, 2mm, 3mm and 4mm

• Gear reduction: 5:1

• Maximum distance between rollers: 6mm

• Roller diameter: 60mm

• Weight: 45.3kg

The links above are affiliate links, so if you click and purchase a mill through these, then we do get a small commission – but every little helps right. However, buying direct isn’t always the best option…. crazy I know.

So if you aren’t in desperate need of a rolling mill right at this minute, I have two suggestions. First of all, I would be going to compare prices from all my favourite suppliers. But don’t forget to check shipping costs too and import duties! My second suggestion: follow all your favourite tool suppliers on Instagram and watch out for sales! TOOL SALES are the best sales in the world, and 10% or even 20% (if you’re lucky) off a $1000 tool is a hell of a lot of a money saved. That can go on even more tools ha ha ha!

Want to learn more?

We would love to welcome you to the Metalsmith Academy where we can help you create the jewellery you always dreamed of.

- Incredible classes with close up videos and crystal clear explanations

- Extensive full colour handouts for all our classes (a firm favorite with our current members)

- Quick win projects and resources. If you don’t have the time to commit to a full class, but want to learn some new skills quickly, these are for you

- Challenges to help get those creative juices flowing

- Active community forums – and when we say active, seriously it’s like a party over there!

- Direct help – Lucy and Vennice are over in the forums every single day to help

- Exclusive discounts

- Tips and tricks galore – you got a problem, we create the content you need to fix it

Just click below to join the family now!